SEKTOR CUTTING EXPERT is engaged in the study, design, development and production of universal and special tools such as carbide, TCT and bi-metal bandsaw blades and the study, research and development of improved solutions for HM, carbide and cermet circular saw blades. SEKTOR CUTTING EXPERT, with a wide portfolio of solutions for all fields of industry, has been extremely successful in proposing and supplying improved tools with remarkable cutting capacity and flawless results to the highest production standards.

Our main commitment and goal is to increasing efficiency for our customers, by targeting and increasing value through each production step to meet the challenges of cost and timing, in an industry market that knows no respite in competitiveness to benefit the customer.

This is why we address the issue of maximum efficiency in our production steps as well, choosing the best sources of special alloy and bimetal steel strips with excellent geometric tolerances and hard metals sourced from Europe to be able to meet the most demanding requirements from the best of operators.

Smooth steel strip before tensioning and grinding of the tooth profile

Steel strip with tooth profile obtained through grinding and tensioning

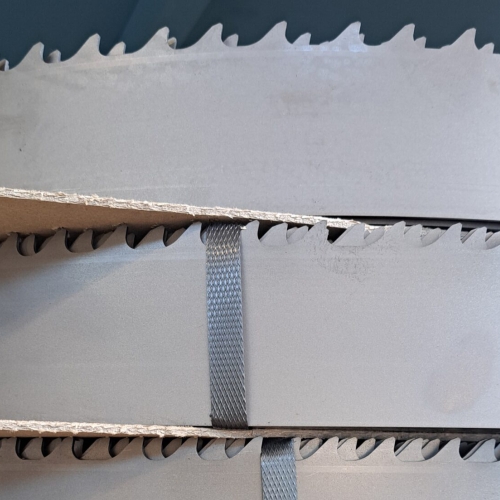

The toothed steel strip, heat and surface treated with shot peening, to improve fatigue resistance

Superfinishing process, for rounding the edges and eliminating rolling tensions

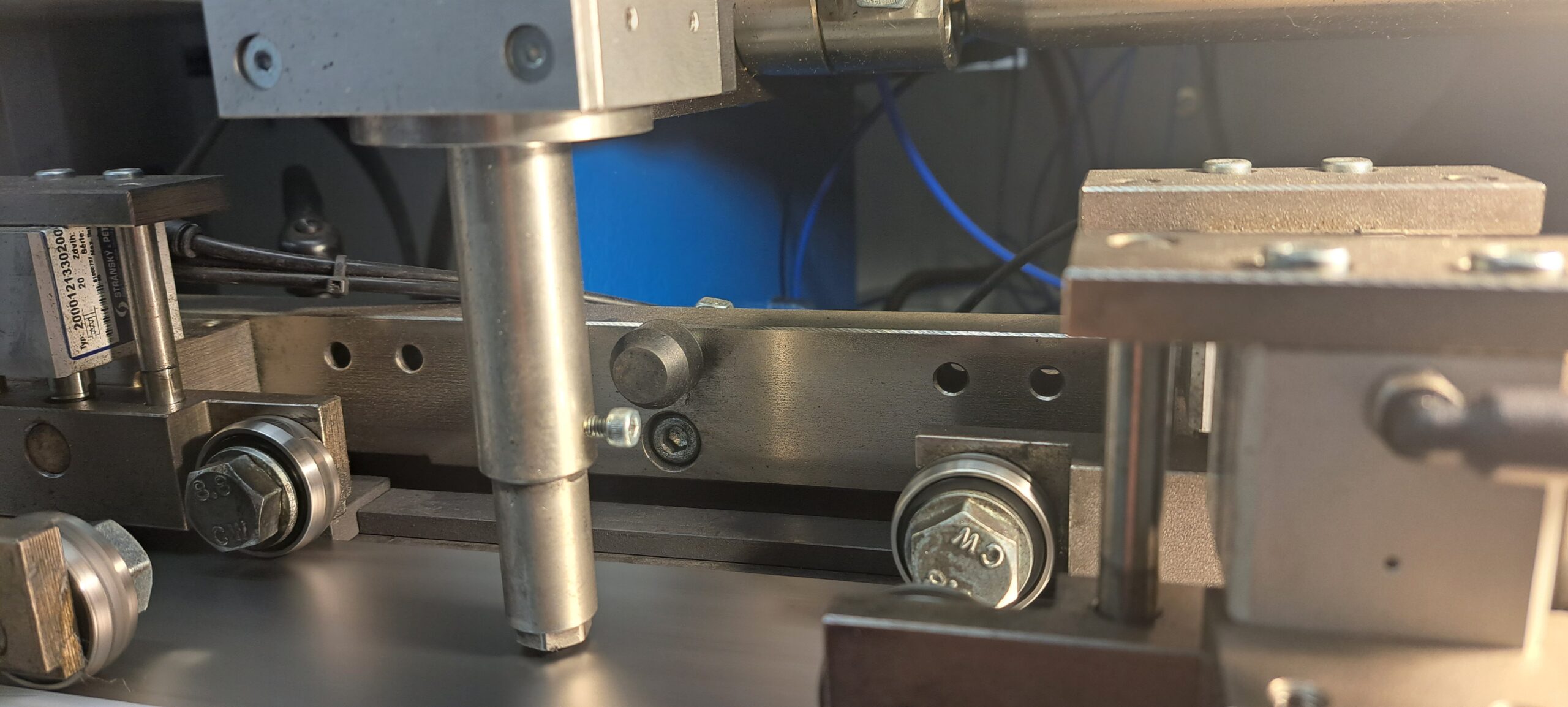

Process to restore flatness and straightness of the strip after treatment

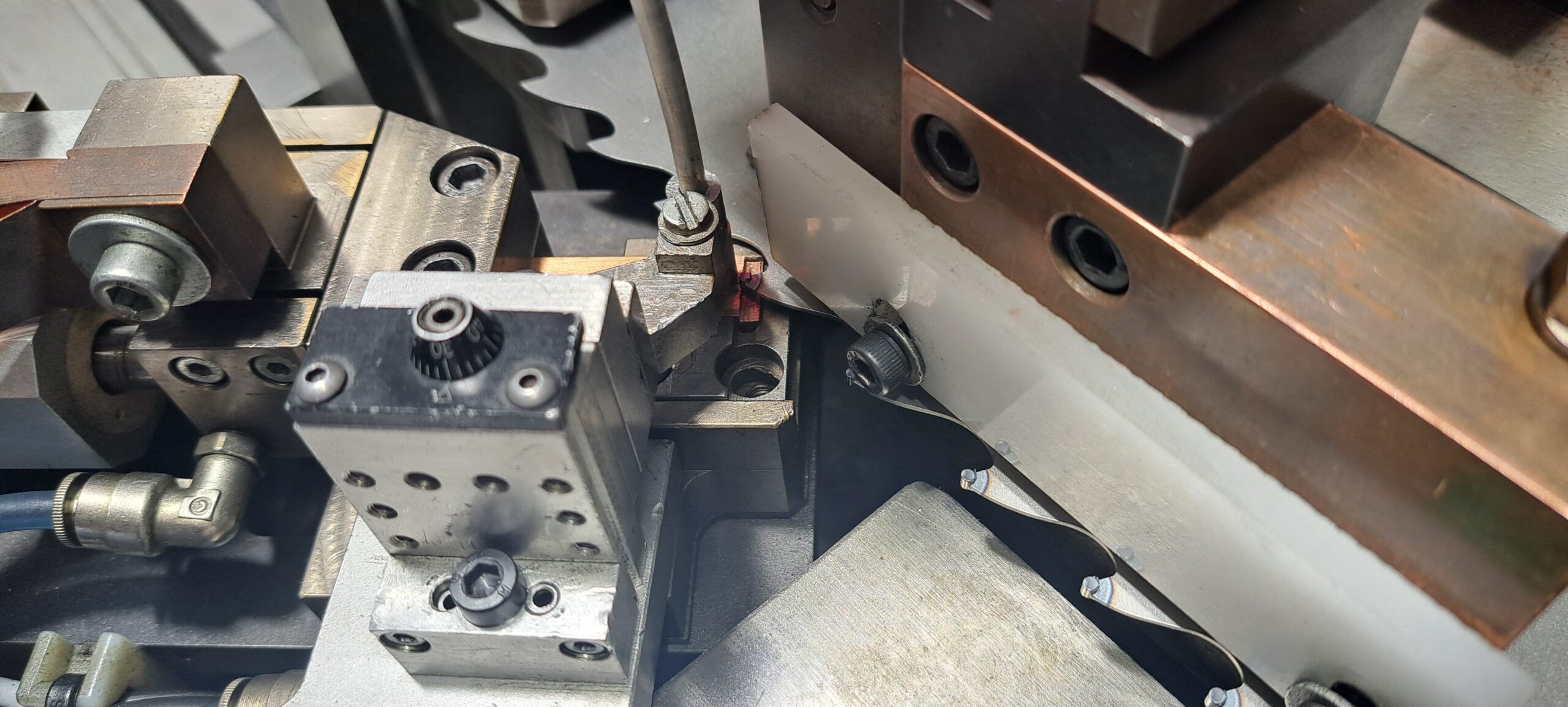

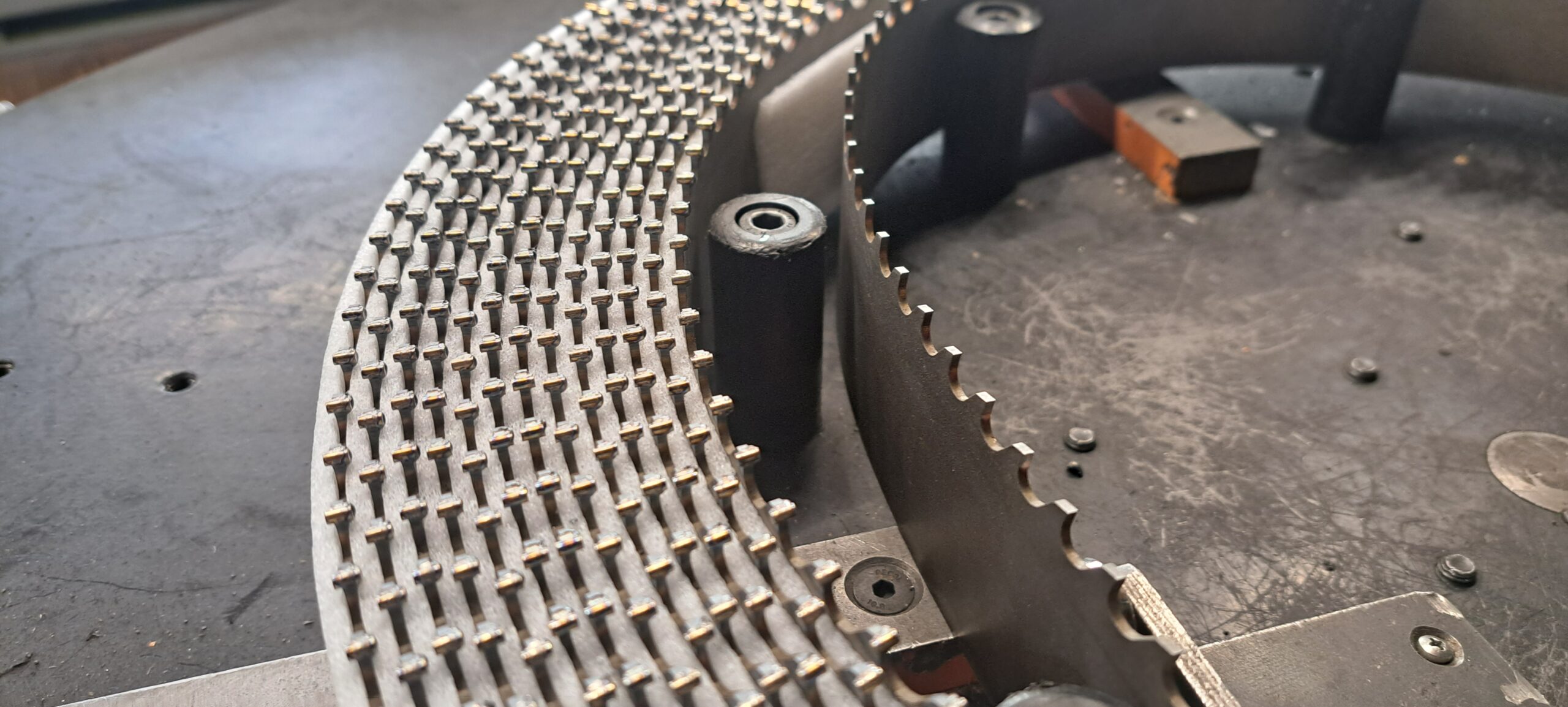

Positioning and welding of cylindrical carbide teeth

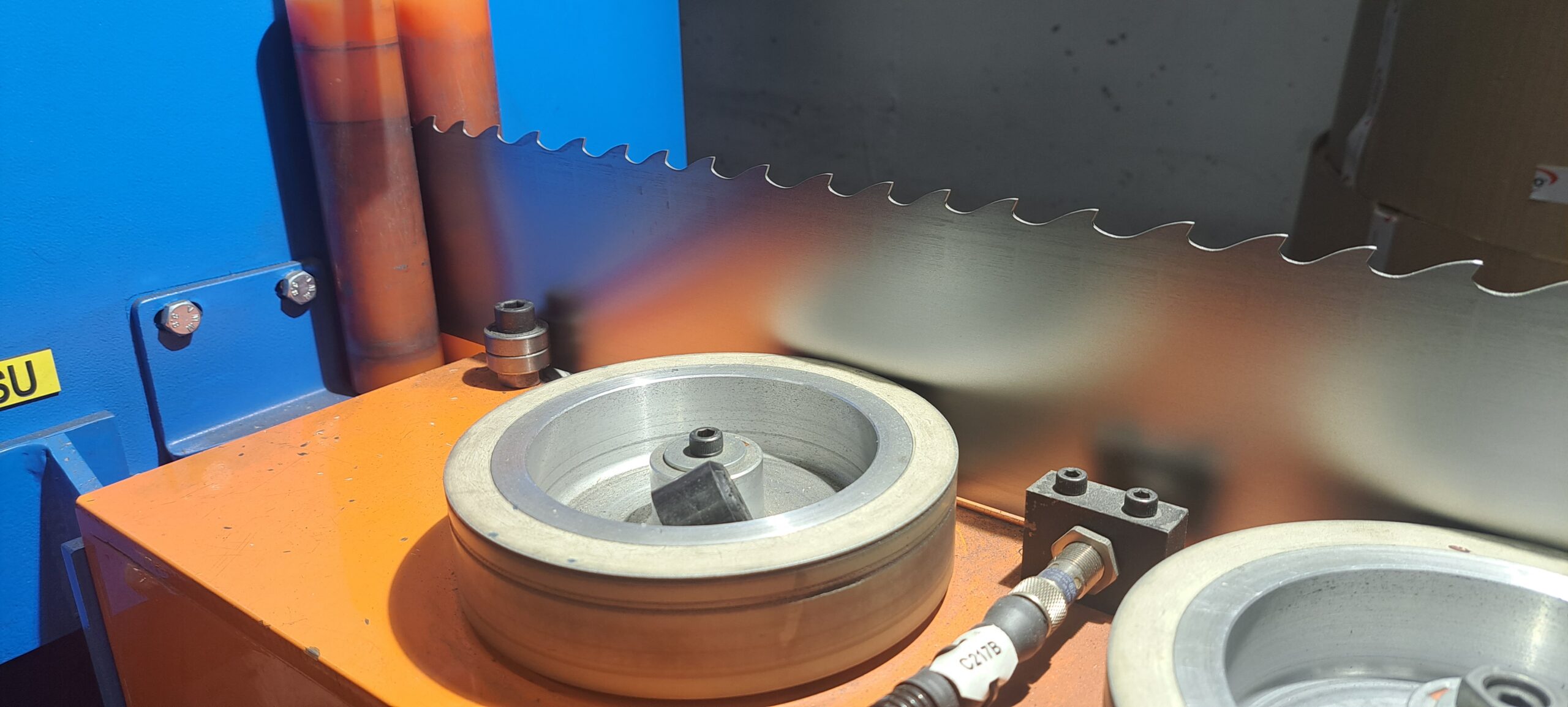

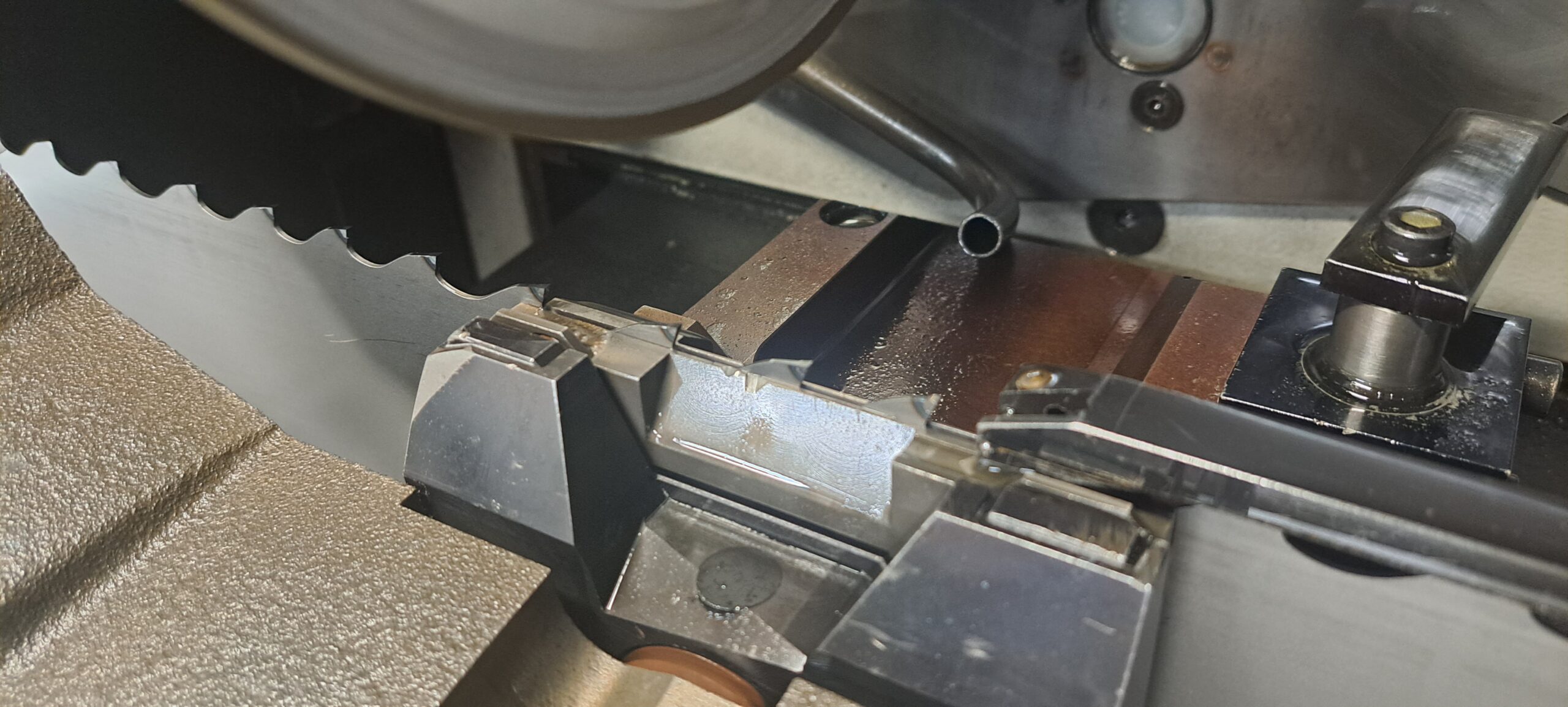

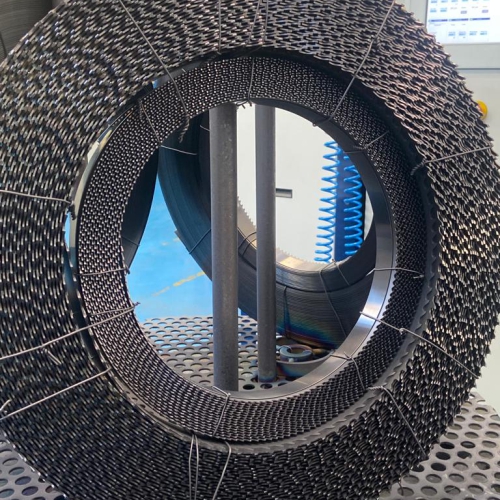

Coil positioned for tooth geometry grinding

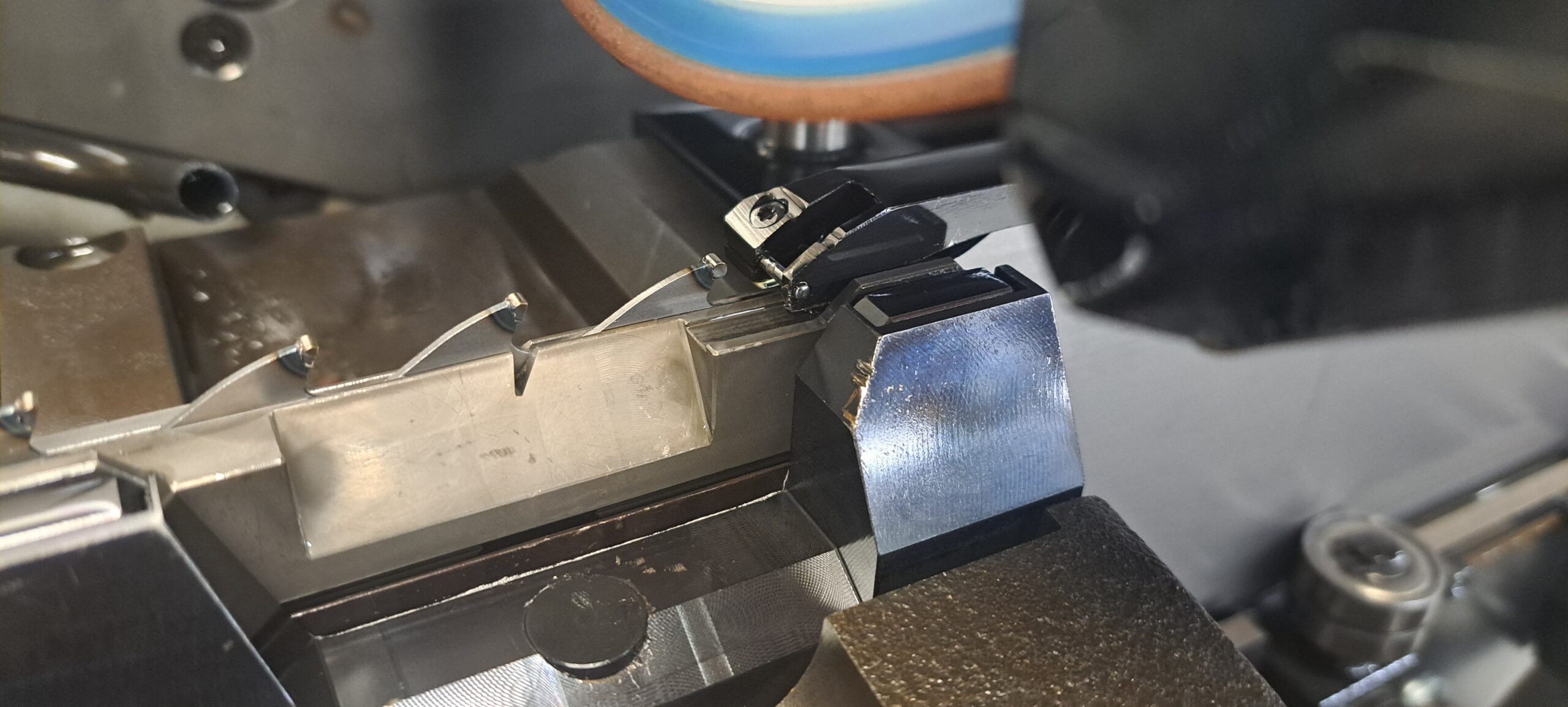

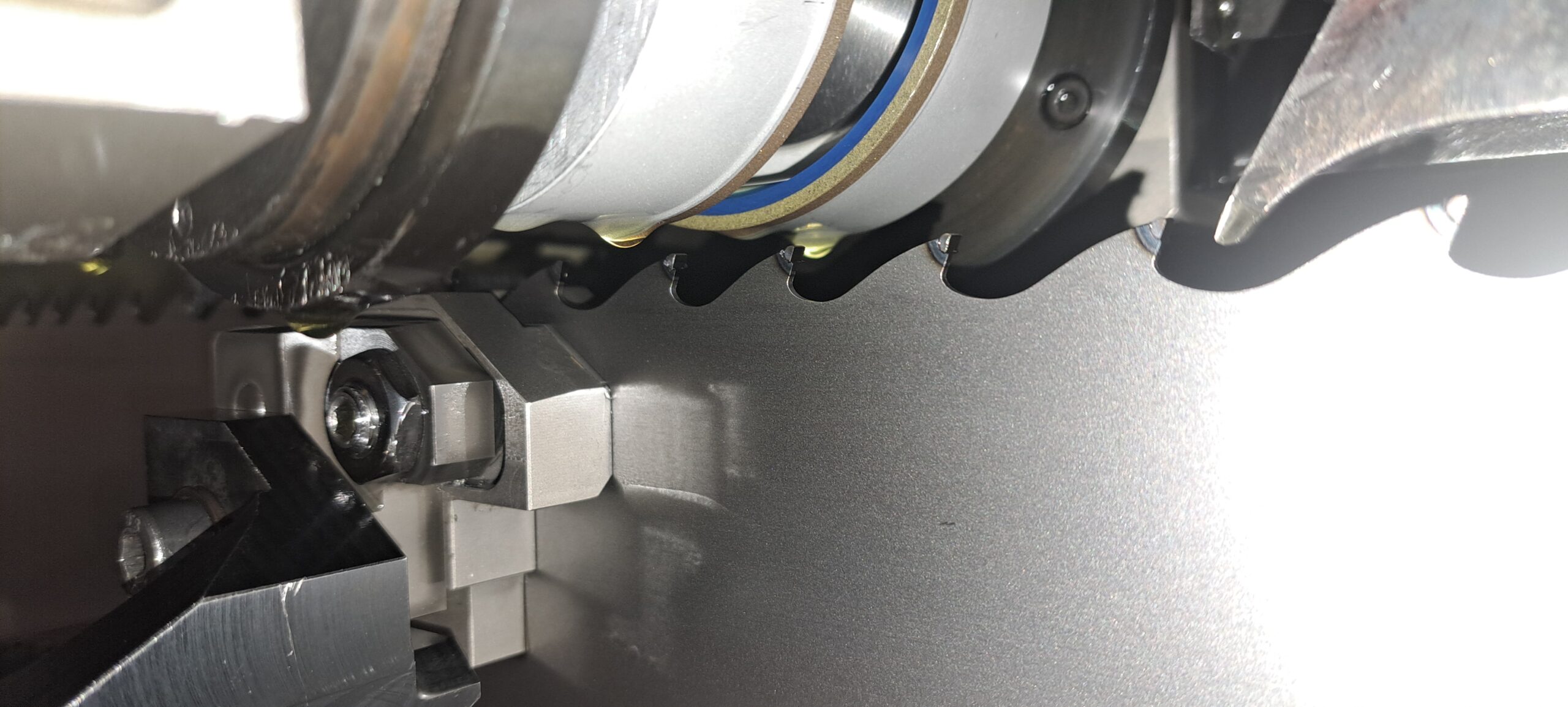

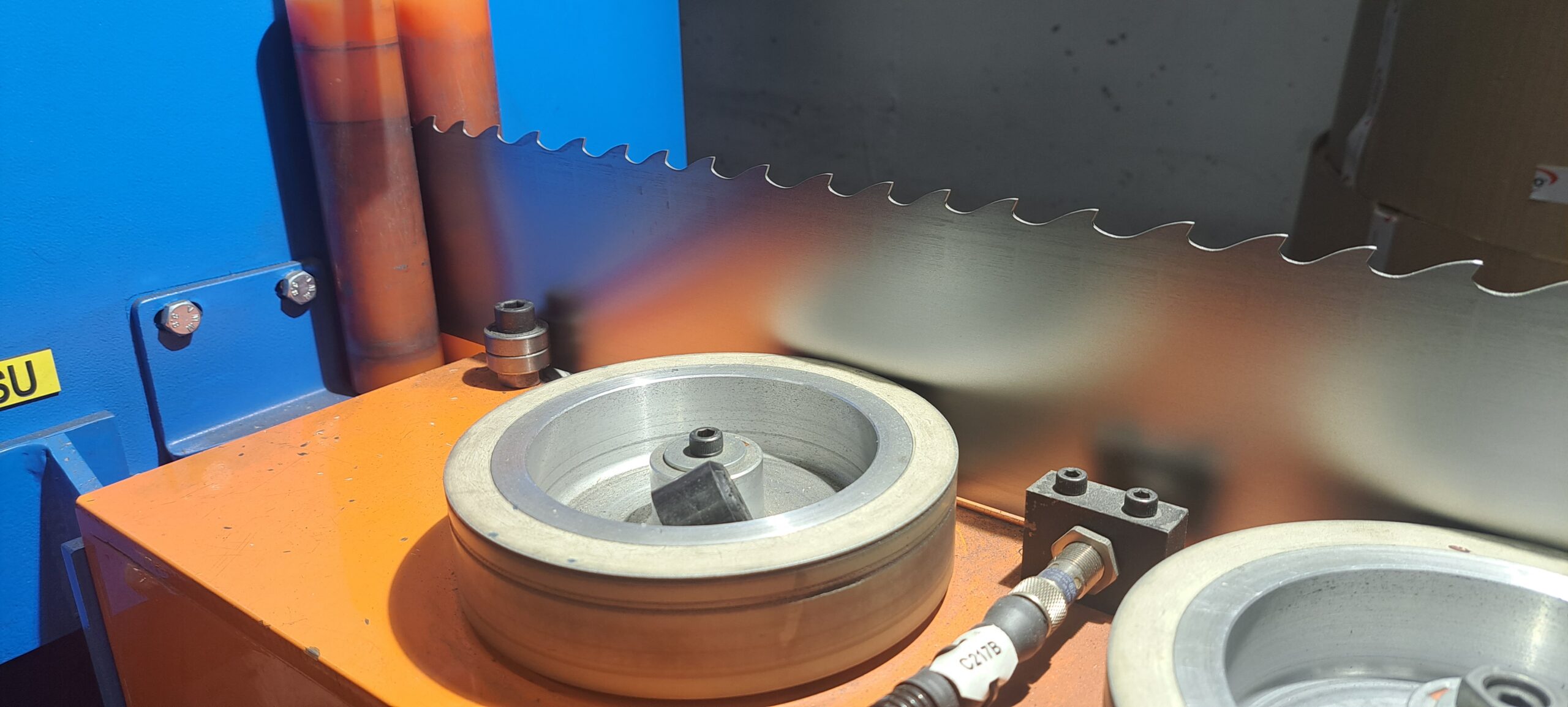

Machine for grinding the upper rake angle of the cutting wedge

Machine for grinding taper on the flanks of the carbide tip

Machine for grinding the lower rake angle of the cutting wedge for obtaining different geometries configurations

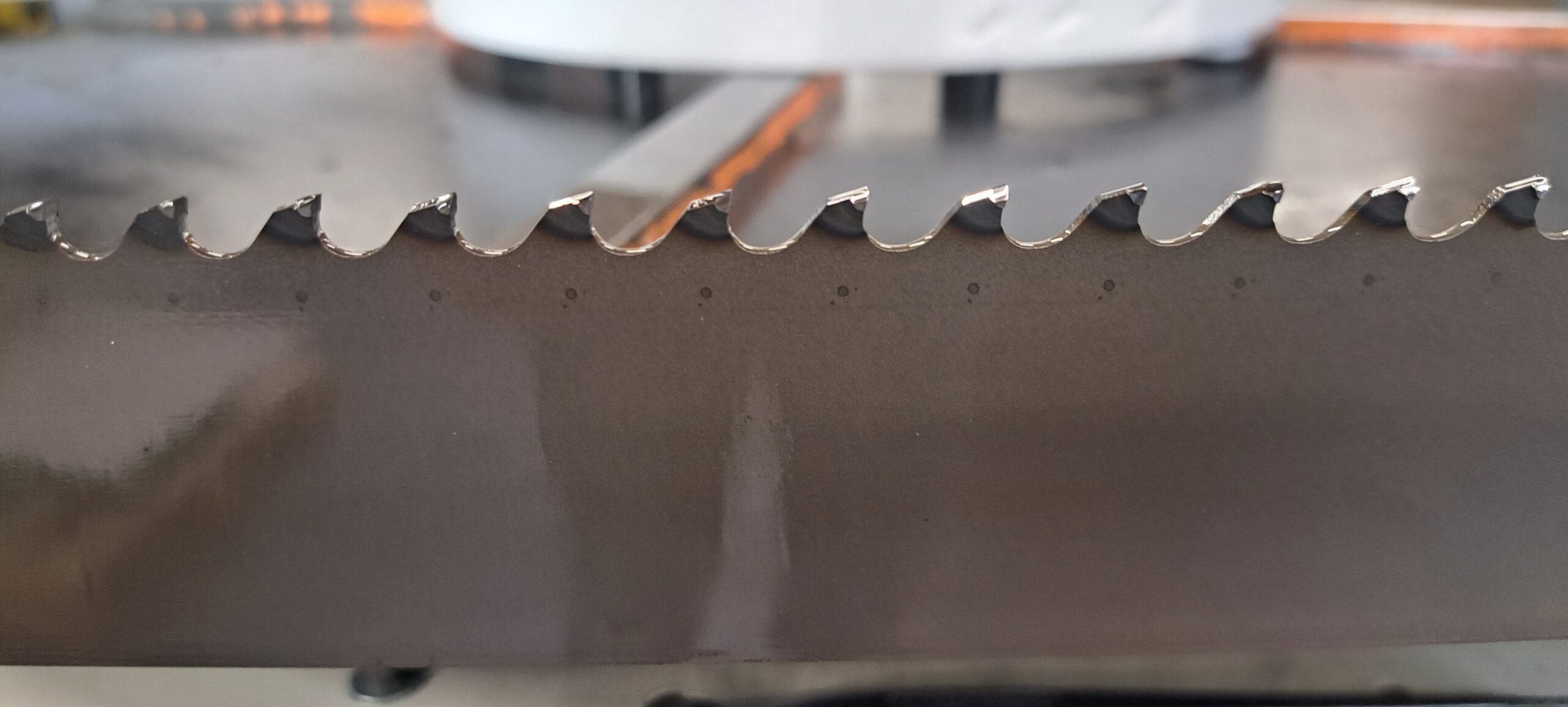

Bandsaw blade with finished ground teeth

Final BREAK-IN or HONING treatment of bimetal or carbide cutting edges and simultaneous removal of oils

Possible PVD coating on finished product coil

Application of protective sheath and packaging

Coil storage of finished blades ready for ring welding or directly for shipping

Cut to length and butt-welded with subsequent controlled annealing treatment

Types of packaging in coil, single ring, single folded blade, blades folded together